Umbrella Factory Tour

How Umbrella Factory Works?

There are more than 2000 umbrella factories in China, and they have one million employees. Only 200 of them embody an output value of over 5 million yuan. A large number of small and medium-sized umbrella factories survive by their “low-grade, low-quality, low-cost” products.

From the very beginning, Huifeng Umbrella Factory has been committed to producing high-quality products. We employ umbrella-makers from Japanese companies with high salaries, produce umbrellas based on British umbrella-making technology, and choose fabrics imported from Taiwan.

Our umbrella factory has specified detailed testing standards and requirements, from controlling the production process to product packaging. We have proudly become a reliable supplier of consumer-trust products. High-quality raw materials, modern production and testing equipment, exquisite technology, and formulas contribute to ensuring the high quality of our products. All these are where Huifeng Umbrella Factory differs from others.

Huifeng Umbrella Factory has formed a scientific, standardized production and management model for decision-making, overall planning, on-site production, and logistics support. Our strict internal control, rational supplier structure, stable customer resources, control of raw materials and finished product inventory, and Dynamic Management Emphasis all contribute to improving and ensuring the company’s operations’ stability and efficiency.

HF Umbrella Factory Tour

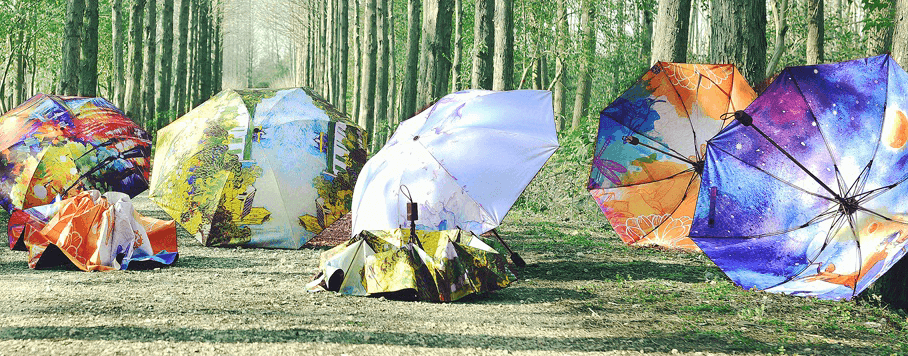

Umbrellas are complicated to craft, requiring careful attention to detail at every step. Our team pioneered printing and fabrication techniques, so your umbrellas will be beautiful and durable.

Huifeng Umbrella Factory created a complete design and manufacturing system to guide the process of manufacturing custom umbrellas from start to finish. Whether you are a designer or not, we will work with you to create umbrellas that fit your specific needs.

Let’s go on a factory tour that will enlighten you about how we take extra care in crafting our umbrellas from start to finish. You would also find that our quality control procedures help keep non-quality standards in check and sift out inferior materials always to provide you with the best results.

Umbrella packing

Umbrella pattern sewing

Clear umbrella workshop

Clear umbrella worker

Umbrella Factory Manufacturing Process

1. We begin at the Fabric factory:

After we have received confirmation from a customer to go ahead with their order, we start our manufacturing process from the fabric factory. Here, we select the fabric for the umbrella canopy based on the client’s choice. If they have no preferences, we make a choice ourselves. There are different types of umbrella fabrics. Our umbrella expert guides or helps us choose the most efficient material that would do the job for the intended purpose. Fabric selection is an integral part of the manufacturing process because the umbrellas are mostly made of a canopy. We can’t afford to make errors here. Our choices are meticulous, per client or advice from our expert. We also thoroughly check the fabric for any deformity, frayed edges, wear, or tears. We only proceed with a material that has passed this test.

2. Next is the Cutting of the Canopy:

This factory stop comes next, depending on the type of printing that the client prefers. If it is silkscreen printing, we must first cut the umbrella canopy into triangular panels for each section. This will enable the printing to be done individually on each panel. For digital printing or sublimation, the print can be done over a wide stretch of fabric before we go ahead to cut.

3. Then Sewing the edges:

It is also known as fabric-edge locking. We proceeded to this part of the factory after we had completed the cutting of the umbrella panels. Now, we can go ahead and sew the outer edges of the fabric. This is done in preparation for the printing process to avoid a rough-looking finish. The umbrella can become frayed and lose its beautiful appearance if we do not lock the edges. We place the edge of the umbrella in a sewing machine and seal it properly. Then, the quality control workers will inspect the quality.

4. We Proceed to do SilkScreen Printing or digital printing:

We move to the printing end of the factory-to-door preferred printing procedure: silkscreen printing. We have decided on this choice because it is one of the longest-lasting types of printing. With silkscreen printing, the rich and vibrant colors of the umbrella pattern will pop out more evidently. It is durable, and the technology has been relied on for years. Printing takes a little time because we are careful to ensure everything is perfect.

5. Then comes the Stitching:

Once the printing is done, we can move on to the sewing department. Here, we start to join the triangular panels of umbrellas together. This is usually done by a sewing machine or sometimes by hand. Each panel of the umbrella is sewn together one by one using careful procedure. This is an essential aspect of work in the factory. If this part is not done correctly, water can seep through the panels and get users wet. Our quality control inspectors ensure that workers run the panels through as many stitches as possible to avoid that.

6. Followed by the Top Stitching:

Still in the sewing department, once the side panels have been stitched together, we must also do the same for the tip. In former times, tip sewing was done manually by factory workers, but today, with the latest technological methods, topstitching is done with the machine. To do this, a small circle is cut out of the top of your umbrella, and then the edges are stitched, leaving a small hole for the top.

7. Then the Band Sewing:

This is where we include the band strap on the umbrella canopy cover. The band is a vital part of the umbrella because it is perpetually left open without it. The strap is therefore attached to the top of the umbrella so that it can be closed. Factory errors occur when there is a failure to attach a band strap to the umbrella. To avoid this, the inspectors go over every canopy to make sure that strap is not missing.

8. We also Nail the tips:

After the circle has been cut, we move on to the next part of the factory, where a special sewing machine is used to attach the tips of the umbrella to the canopy. The umbrella tip is a piece of metal or plastic attached to each rib of the umbrella. This fastens the umbrella canopy to the rip so that it becomes more secure.

9. Next is the Assembling:

Now that all the parts of the umbrella are ready, we piece each section together. This is the last stop in the sewing corner. To attach the canopy to the ribs, this can only be done manually. No fully automated sewing machine can do this, although some companies use semi-automatic sewing machines. Workers stitch each panel to the umbrella frame by hand until the entire canopy is safely attached to the canopy. This makes the umbrellas more durable and longer-lasting.

10. Fix in the Handle:

Now that we’re done with the sewing department, it’s time to fit in the handle and the top. There are different ways to fit in the umbrella handle, and this usually depends on the type of material chosen for the handle. In this department, the handle can be attached either by screwing it into the top, heating up the shaft (handle), melting it to the top, or gluing it to the top of the umbrella through the little hole made in the canopy.

11. Almost there – the Finished Product:

This is the end of manufacturing the umbrella. However, there is one little detail left—quality control checks. Although the inspectors have gone through each process from the beginning of the tour, they still need to do the final examinations. These checks certify that there is no problem with the umbrella, and it is approved to be packaged and moved to the warehouse or shipped off to the client.

12. Finally, Off to the Warehouse:

All certified umbrellas now have our mark of standard quality, and clients can rest assured of good umbrellas that can stand the test of time. From the warehouse, clients can pick up their orders, and wholesalers can also get their products from there. The warehouse is the last point of stop for our factory tour.

The process of making an umbrella is complicated yet fascinating. A virtual tour can, at best, explain the process to you. You can only enjoy the real deal when you see the process and output for yourself!

The R&D Model spurs our Growth.

We insist on the R&D idea of “Fashion, stand wear and tear, make varied.”

Hf umbrella factory always keeps developing materials and patterns, improving quality day by day. Huifeng Umbrella Factory has eight invention patents, 35 utility model patents, two design patents, and seven overseas invention patents. Our umbrella factory has produced thousands of modern automatic, multifunctional environment and sun umbrellas.

By establishing close contact and cooperation with the universities and independent designers, our company keeps absorbing new concepts and technologies so as to develop more excellent products for our customers. To gain new aesthetic concepts and better know-how of creative designs and accumulate more design resources for our designers, we worked with the universities in organizing a variety of creative design activities.

Over the past few years, our company has established continuous cooperation and shared research achievements with universities like the Central Academy of Fine Arts so as to integrate our research resources and increase the technological content of our products.

Ordering Custom-Made Umbrellas From HF Umbrella Factory

Custom umbrellas help to promote your brand

If this tour has spurred you to make an order for your custom-made umbrellas, you’re lucky. Building an umbrella for clients is what we know how to do best. All we need is a little information from you, and we get to work. To order your custom-made umbrellas, here is what you need to do.

Select Your Style and Materials:

- How do you want your umbrellas to look like? What materials do you prefer it to use? This is an essential factor to consider as you plan to send your designs to us. An umbrella can take on different styles and shapes. This depends on the need the umbrella is built to take care of. Some umbrellas are better suited for the sun, while some work well in the rain. Some are for adults, some are for children. Many other factors determine the style and materials an umbrella uses. Decide on all this and choose the preferred look you want your umbrella to take before moving on to the next step.

Select the Umbrella Design:

- Even if you are going for an umbrella with a plain canopy, it is ideal for us to know this. If not, choose a pretty design that we would print on the umbrella. This can be floral images, city skylines, beautiful scenery, and many more. Save this design in a Vector PDF or EPS. File and send it to us. We also help you create designs if you are unable to do it yourself. Let us know what you would like, and we would get it done.

Decide on Size:

- What is your preferred umbrella size? Different sizes are ideal for various purposes. Find this out and have it settled as you contact us. If you’re not sure about this, our umbrella expert can walk you through the process and help you decide.

Send your details and information:

- Now that all this is settled, we are ready to get your umbrella custom-made at our factory. Send us your design and specifications at info@hfumbrellas.com so that we can begin to work on your sample. Once this is done, we would send you a sample for approval. If our design matches what you intend and desire, we can begin manufacturing your umbrella at our factory.

It’s easy! Let us handle your custom umbrella needs.

Our Customers