To preserve our resources for future generations and reduce harm to the environment, many manufacturers are looking for environment-friendly and sustainable approaches to creating products. Problems like global warming and plastic pollution are becoming an increasing threat to the environment; hence, the focus of many is on sustainability. This focus is reflected in the shift from plastic shopping bags to paper options and even the production of rPET umbrellas as a solution to global warming and plastic consumption. This guide will discuss RPET umbrellas, how they are made, and their benefits.

Table of Contents

What are RPET umbrellas?

Before we move on to other details, let’s start by exploring the concept of rPET umbrellas and why they exist. Research shows that every piece of plastic ever made still exists today. This is because plastics are non-biodegradable—they cannot break down and disappear into the soil like many other materials. Most of these plastics eventually end up in water bodies and landfills, contributing to various environmental challenges.

How do we solve this? While it is almost impossible to eliminate the use of plastics, experts have devised a solution that helps manufacturers and the environment—plastic recycling. This means that rather than producing more plastics, why not reuse or repurpose existing ones for various functions? This is how rPET umbrellas were born.

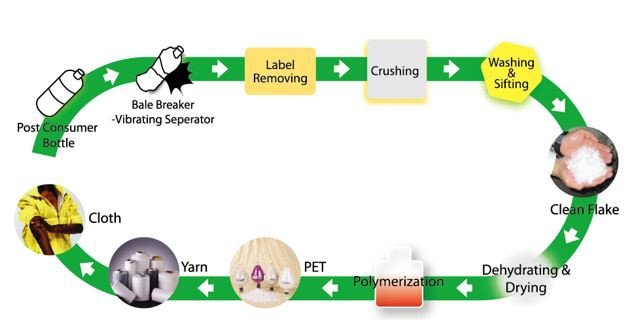

rPET umbrellas mean recycled Polyethylene Terephthalate umbrellas. Polyethylene terephthalate is a plastic used to make various consumer products like beverage bottles, packaging materials, and more. However, this PET can be recycled, which converts it into rPET, which can then be used to make new products like umbrellas. Umbrellas made out of recycled or repurposed plastics are rPET umbrellas; now, let’s see how they are made.

The Process of Making RPET Umbrellas

If you are wondering how these RPET umbrellas are made, here are the steps for their production.

Collection:

In the first stage, all used plastics are collected and sorted out by type. Not all plastics can be used, so you check for a “recycle” or “rPET” sign to know if it is good for use. Once this is done, you can move to the next stage.

Cleaning:

After sorting all collected plastic bottles, you will proceed to clean them and remove contaminants. Some plastic bottles may still have their content in them; you will have to get rid of the content and then sort all the plastics by color.

Shredding & Fiber Extraction:

In this next stage, you shred all the plastic bottles into PET chips; these chips are then melted, spun, and prepared for the extrusion process where they pass through microholes. The result of this process is fiber production, which is used for the next stage.

Yarn Production:

The fiber produced from the extrusion process is spun into polyester yarn. The fiber looks like cotton, with a white color; any other color suggests the presence of impurities.

Umbrella Fabric Production:

Finally, the polyester yarn is woven into the fabric that is used to make the umbrella canopy. The manufacturer attaches other umbrella parts like the ribs and handle. The fabric can be dyed in different colors and various designs can be etched on it. At this stage, your rPET umbrella is ready for use.

Advantages of rPET Umbrellas

The production of rPET umbrellas has several benefits for individuals, umbrella manufacturers, and the environment at large. Some of these benefits are highlighted below.

Environmental Impact:

One of the benefits of rPET umbrellas is the positive impact it has on the environment. By producing more RPET umbrellas, you reduce the number of plastics that fill up water bodies and cause harm to fish and other aquatic animals. Also, rPET umbrellas reduce the amount of plastic that goes into landfills, preventing environmental pollution.

In addition, the production of rPET umbrellas uses less energy than other materials, and they also help to save energy compared to the production of pure polyester; this reduces the carbon footprint of your manufacturing processes, leading to sustainability.

Durability:

Another benefit that rPET umbrellas offer is durability. It can withstand stress and strong winds and is resistant to shrinkage and wrinkling, making it a great choice if you are looking for a long-lasting umbrella. In addition to its durability, it also weighs less than traditional umbrellas yet stays strong when the wind gets strong.

Water Resistance:

Naturally, polyester materials are water resistant and so is the rPET umbrella. The best umbrella choice is one that can prevent leakage through its canopy and this is one of the benefits of rPET umbrellas over other options.

The Best RPET Umbrella Manufacturers

Deciding to switch from traditional umbrellas to rPET umbrellas is a start if you want to lead an environment-conscious life. You can start with little things, such as using a piece of protection that reduces the number of plastics that lie around. However, to do this, you need to find a reliable RPET umbrella manufacturer that is as focused on sustainability as you are.

HfUmbrella is one of the best umbrella manufacturing companies in the world and the first to produce rPET umbrellas. Not only do we produce high-quality umbrellas, but we also offer customization options to allow you to create umbrella pieces that showcase your passion and likes.

Hence, you can start your journey to sustainability by getting bulk RPET umbrella orders from us for your home and offices and as gifts for your favorite people.